The Outdoor Warehouse is proud to offer one of our very best flagpoles. Quick and easy installation and fast shipping.

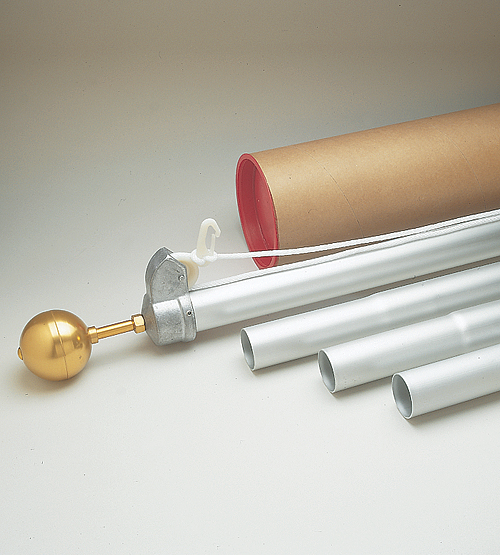

20' and 25' flagpoles that can be shipped via parcel carrier!

These popular flagpoles are:

- 2 Times the thickness of a residential pole

- Simple to install and come complete in a boxed set with all the standard accessories.

- Available in satin, clear, bronze, and black anodized finishes.

- Same day via parcel carrier, unlike traditional commercial grade flagpoles.

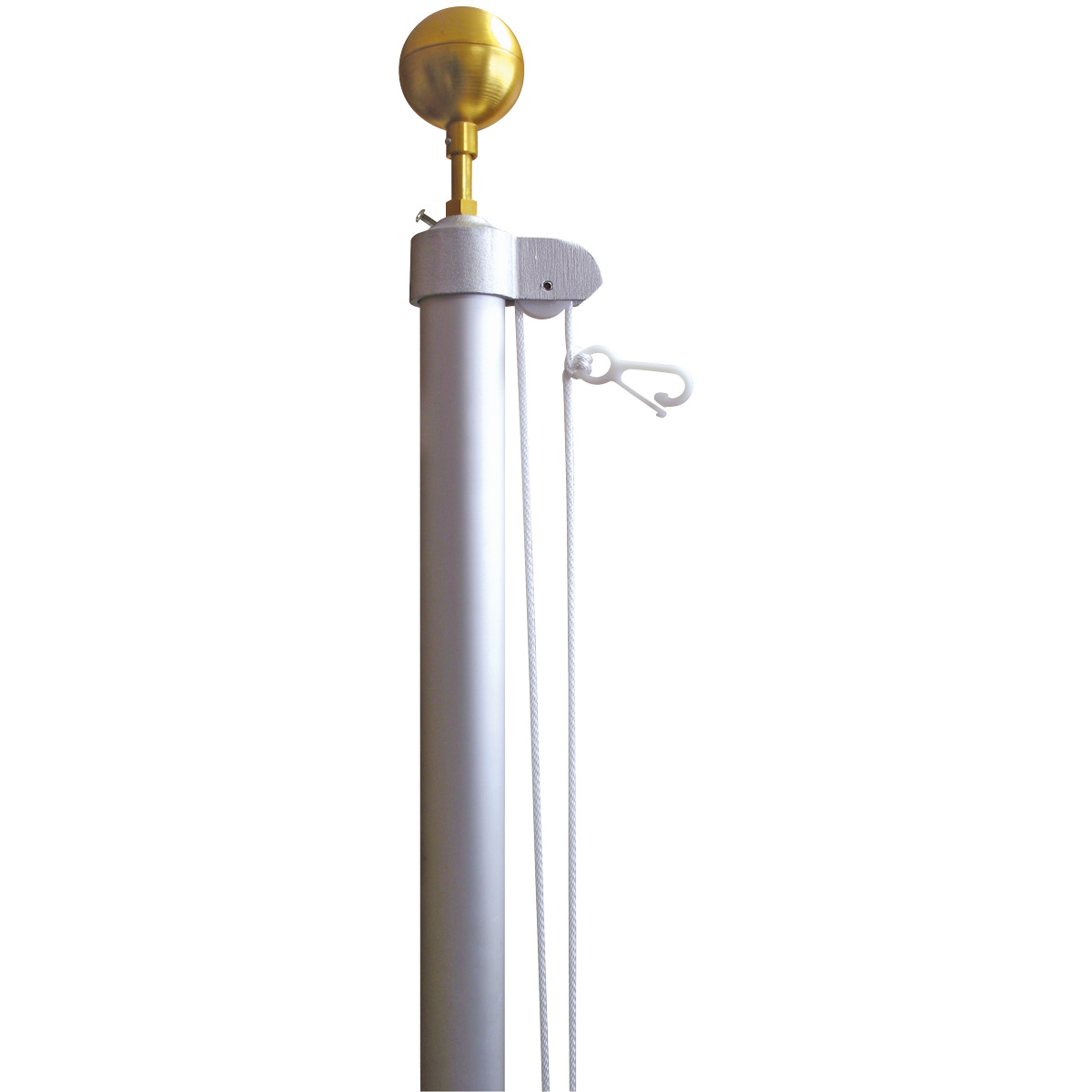

- Pole is tapered from 3" at the bottom to 1 7/8" at the top

- Wall thickness is 1/8", residential poles are only 1/16"

- 20' Sectional Flagpole weighs 43 lbs.

- 25' Sectional Flagpole weighs 52 lbs.

The maximum flag size for this pole is 3' x 5'. If you are going to fly two flags then the maximum flag sizes are two 2' x 3'.

This line of commercial grade flagpoles manufactured using 6063-T6 aluminum tubing, can be used in both residential and commercial applications. These cone tapered flagpoles have elements of a one piece flagpole with the advantage of free shipping costs within the 48 states. Hawaii and Alaska are not included.

Made in the USA

Sectional Aluminum Flagpole Installation Instructions

1. Dig foundation hole four to six times the butt diameter of the flagpole.

2. Set the foundation tube so that the top of the foundation tube is two inches above grade.

3. Plumb foundation tube and brace so that it will not move during the pouring of the concrete.

4. Pour concrete and trowel up even with the top of foundation tube. Keep inside of foundation tube dry.

5. Lay pole on sawhorses and unwrap. Check flagpole section ends for any burrs. If any are found, file them off and wipe the area clean.

6. Put sections of pole together using liquid soap or talcum powder at joining areas if needed.

7. Install cap-style truck at top of pole making sure set screws are well tightened and truck pulley is aligned with cleat.

8. Thread ball into truck by turning stem of ball. Secure ball into truck by tightening nut on ball spindle and set screw located in flagpole truck.

9. If flash collar is provided with pole, slide collar on from the bottom of pole to above cleat level and attach cleat with one screw to hold flash collar until after erection of pole.

10. Thread rope through sheave (pulley) of truck, and tie the ends together so that the rope will not drop out of the sheave during erection of the pole.

11. Erect pole into foundation tube and center it. Turn so that the cleat holes are in the direction desired. Recommend to position cleat away from prevailing winds.

12. Place wood wedges (supplied by others) between the pole and foundation tube and plumb pole.

13. Pack dry sand between the pole and foundation tube. Leave two inches void at the top and fill with waterproof sealant to keep water out of the sand.

14. If using a flash collar, remove cleat, slide collar down and replace cleat. Caulk between the collar and the pole with clear waterproof sealant.

15. Loop snaps on rope ensuring they are spaced properly for flag size being used.

Caution: Extreme care must be exercised when installing flagpoles near overhead power lines or when digging in the vicinity of buried cable or piping. Contact your local authorities before any digging.